Authorized South-East Asia Representative

![]()

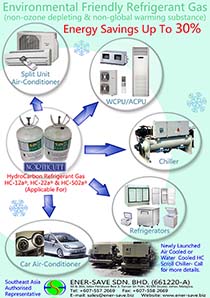

HYDROCARBON REFRIGERANT GAS

HC Case Study 1

Client: NatSteel Holdings

Contact Person: Mr. Akhtar

Address: Kling Road,

Tel: Private

A/C Name: PE23 (2HP, MC Quay, 18,000 Btu) Demo Unit

Existing Refrigerant Gas: R22 (HCFC)

New Refrigerant Gas: Hydrocarbon Refrigerant R22-a (HC)

Location: Guard House

Energy Savings Verification

BEFORE replacing Hydrocarbon Refrigerant Gas

Recording Time: 04/02/09 14:20:00 – 10/2/09 14:18:00

Total Power Consumption (A1): 221318Wh – 231Wh = 221,087 Wh

AFTER replacing Hydrocarbon Refrigerant Gas

Recording Time: 11/02/09 14:20:00 – 17/02/09 14:18:00

Total Power Consumption (A2): 176970Wh – 21922Wh = 155,048 Wh

Data Finding

PE23 (2HP, MC Quary, 18,000 Btu) |

||

Descriptions |

Before Replacing HC Refrigerant |

After Replacing HC Refrigerant |

Date & Time of Recording |

04/02/09 14:20:00 – 10/2/09 14:18:00 |

11/02/09 14:20:00 – 17/02/09 14:18:00 |

Total Recording Duration |

144 Hours |

144 Hours |

Refrigerant Weight (kg) |

2.2 |

0.88 |

A/C Temperature Set Point (oC) |

20 |

20 |

Outdoor Temperature (oC) while start recording |

NIL |

NIL |

Room Temperature (oC) |

19 - 22 |

19 - 22 |

Relative Humidity (%RH) |

50-70% |

50-70% |

Low Side Pressure (PSI) |

60 |

52 |

High Side Pressure (PSI) |

NA |

NA |

kWh Consumption during recording period |

221,087 Wh |

155,048 Wh |

Average hourly Power Consumption (Watt) |

1,535.33 |

1,076.72 |

Operating Hour (Hour(s)) |

24 |

24 |

Operating day |

30 |

30 |

Savings achievement |

(221,087 – 155,048)/ 221,087 = 29.87% |

|

Monthly Savings (kWh) |

(1535.33 – 1076.72)/1000 x 24 x 30 = 330.20 kWh |

|

SPECIALISE IN:

Energy Savings System, Mechanical & Electrical Engineering, Control Switch Board / DB/ SubDB and MSB, Power Electrical & Control Wiring Works.

ENER-SAVE SDN BHD

30 & 30A, Jalan Perlaluan Besi 3, Taman Sri Putri, 81300 Skudai, Johor, Malaysia.

Tel: +607-557 2669,

Fax: +607-558 2669

E-Mail: sales@ener-save.biz

Powered by: Ener-Save Sdn Bhd Web Master Group | Home | Company Profile | Products | Past Experiences | Case Studies | Contact Us |

Copyright © 2015 All Rights Reserved